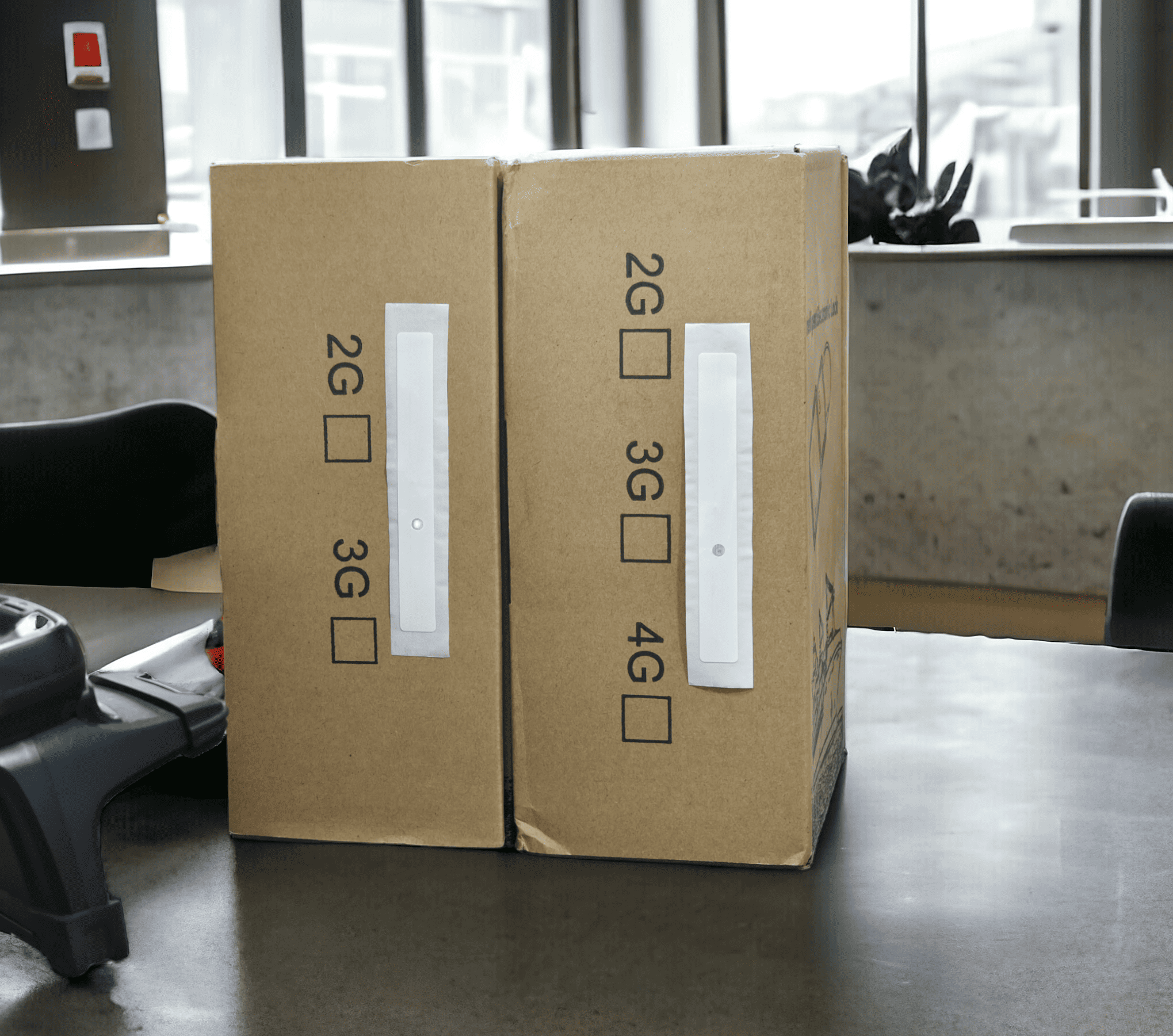

Discover LED RFID LABEL

The LED RFID LABEL is a passive RFID tag equipped with integrated LED lights that indicate specific items in pick-to-light systems. It operates on UHF technology, allowing for efficient long-range scanning and data retrieval, while its printable surface enables customization for enhanced inventory management and document tracking.

LED RFID LABEL - Technical Specification:

Characteristics:

The LED RFID LABEL is a UHF passive RFID tag featuring integrated LED lights for efficient pick-to-light systems and customizable printing options. Its durable, compact design enhances inventory management and document tracking in various environments.

General Specifications

Product Name: LED RFID Label

Model Number: KS101L

Type: Passive RFID Tag with LED Indicator

Dimensions: 100*12*0.28mm (Aluminum antenna 95*3mm)

RFID Specifications:

Frequency: UHF (Ultra High Frequency)

Operating Frequency Range: 920.5-924.5Mhz

Read Range: 150cm on Air-Free (depends on reader)

Protocol Compliance: KX2005XB-L/T (Protocol: ISO18000-6C GEN2)

LED Specifications:

LED Color: Red, Green, Blue

LED Activation: triggered by RFID reader

Power Source for LED: Powered by RFID reader's signal (no battery required)

Printing Specifications:

Printable: Yes

Printable Area: 100mm * 12mm

Material: Polyester

Applications:

Ideal for use in warehouses, distribution centers, retail environments, and inventory management systems.

Compliance:

Standards Compliance: ISO18000-6C GEN2

LED RFID LABEL

The LED RFID Label is a specialized RFID tag that combines advanced tracking capabilities with visual indicators. It’s designed for securing and monitoring assets effectively.

UHF RFID Technology: Operates at ultra-high frequencies, enabling long-range reading (typically up to 10 meters or more, depending on the reader).

Tamper Detection: Equipped with features to detect unauthorized access or tampering. Once the label is compromised, it can trigger an alert, ensuring real-time security.

LED Indicators: Built-in LEDs provide immediate visual feedback on the status of the label (e.g., secure, tampered, or normal).

Durability: Designed to withstand harsh environmental conditions, making it suitable for various industries like logistics, manufacturing, and warehousing.

Versatile Design: Can be attached to a variety of surfaces, enhancing flexibility in applications.

Benefits Of LED RFID LABEL

Increased Efficiency :-

Faster Picking: Lights guide workers directly to the items, reducing search time.

Streamlined Operations: Minimal training required as the visual cues are intuitive.

Improved Accuracy :-

Reduced Errors: Clear visual indicators minimize picking mistakes, leading to fewer order discrepancies.

Real-Time Confirmation: Systems can confirm items picked in real-time, ensuring accuracy.

Enhanced Inventory Management :-

Better Tracking: RFID tags provide real-time visibility of inventory levels and locations.

Automated Updates: Inventory data can be automatically updated, reducing manual entry and potential errors.

Cost Savings :-

Labor Efficiency: Less time spent searching for items translates to lower labor costs.

Reduced Returns: Fewer picking errors mean lower costs associated with returns and customer dissatisfaction.

Increased Productivity :-

Faster Order Fulfillment: Quicker picking processes lead to faster order processing and shipping.

Higher Throughput: More orders can be processed in the same amount of time, enhancing overall productivity.

Enhanced User Experience :-

Simplified Tasks: The visual nature of the system makes it easier for workers to complete their tasks without constant supervision.

Lower Stress Levels: Clear guidance can reduce the pressure on workers, leading to a more pleasant work environment.

Flexibility and Scalability :-

Adaptable to Various Layouts: Systems can be configured to fit different warehouse designs and workflows.

Easily Scalable: Additional lights and RFID tags can be added as inventory needs grow.

Better Safety :-

Reduced Walk Times: Less time spent moving around the warehouse can decrease the risk of accidents.

Clear Work Areas: Organized picking paths can help keep the workspace tidy and safe.

Data Collection and Analytics :-

Performance Metrics: Collecting data on picking times and accuracy allows for continuous improvement and optimization.

Informed Decision-Making: Analytics can inform inventory management and operational strategies.

Enhanced Communication :-

Immediate Visual Cues: LED indicators serve as a direct line of communication for picking instructions, reducing misunderstandings.

Smart Security, Visible Assurance.

The LED RFID Label provides cutting-edge security and tracking capabilities, ensuring that your assets are always protected. With advanced RFID technology and built-in LED indicators, this label offers both real-time monitoring and immediate visual feedback.